Es una empresa de alta tecnología especializada en investigación, desarrollo.

Es una empresa de alta tecnología especializada en investigación, desarrollo.

Product Oerview

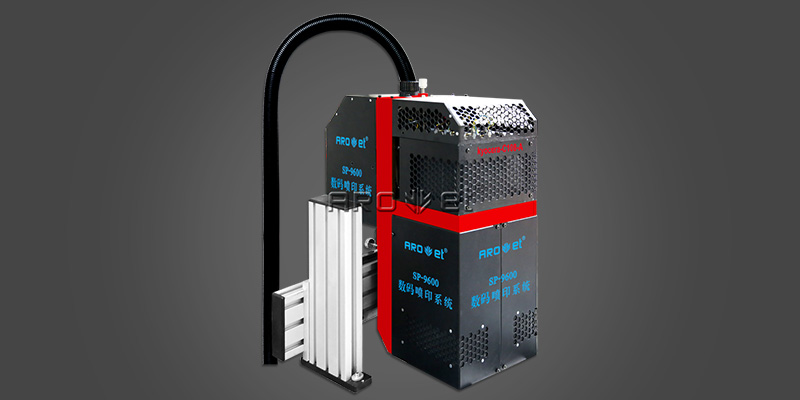

AROJET SP-9600 wide-format digital variable data UV inkjet printing machine adopts KYOCERA industrial piezoelectric printhead with 108mm wide-format configuration. A small number of printheads can be used to achieve large format inkjet printing, to reduce complicated location adjustment. The printing speed is up to 150mm/min. with photo level resolution and minimum text height of 1mm. High image quality and high resolution and grayscale can be gained.

The UV curing ink used can be printed directly on various materials, suitable for a large variety of printing materials, such as printing variable barcode, two-dimension code, character, number, etc. on glass, acrylic, wood board, ceramic tile, metal plate and so on.

SP-9600’s human-friendly software and optional streamlined printing modes, adapt to industrial online production, and meet customers more extensive inkjet printing requirements.

Product Features

◈ Wide-format inkjet printing, reduce number of printhead.

◈ Resolution: 600*300dpi, speed: 150m/min.

◈ Resolution: 600*400dpi, speed: 100m/min.

◈ Resolution: 600*600dpi, speed: 60m/min.

◈ KYOCERA print head, durable,long life and high quality.

◈ Excellent blackness and high definition.

◈ Outstanding inkjet printing stability.

◈ The minimum character height printed is 1mm.

◈ Can both be installed in customer’s production line and be self-equipped platform

◈ 24*7 hours continuous running, improving production efficiency.

Product Specifications

Model: | SP-9600 | Printing software: | MagicData variable data-editing software |

Print head type: | Industrial piezoelectric print head (KYOCERA) | SDK: | Provide interface to support second development |

Print head life: | 100 billion actuations per print head | Ink control: | Negative pressure for ink control, positive pressure for nozzle cleaning |

Print head material: | Stainless steel, Nickel alloys & Epoxy adhesive | Ink type: | High-quality Eco-friendly UV ink |

Print head width: | 108mm (single print head) | Ink color | Single color |

Nozzle quantity: | 2656 pcs (single print head) | Curing type: | UV-LED curing |

Nozzle rows: | 4 rows | Printing speed: | 0-150m/min. (Affected by material, resolution, environment, platform etc. factors) |

Printing modules: | 4 groups | Lengthways printing precision: | 600dpi |

Max. width of printing: | 864mm | Crosswise printing precision: | 200dpi-1200dpi adjustable |

Distance from print head to material: | 0.5mm-2mm | Weight: | 270KG |

Material feeding way: | Single piece, roll to roll | Size: | 1.39m*0.83m*1.50m (print head case+curing case) |

Power supply: | AC 100V-240V, 50Hz-60Hz | Working temperature: | 5°C-40°C |

Interface type: | USB 3.0 optical fiber data transmission | Environment humidity: | 20%-65% RH |

Product Videos

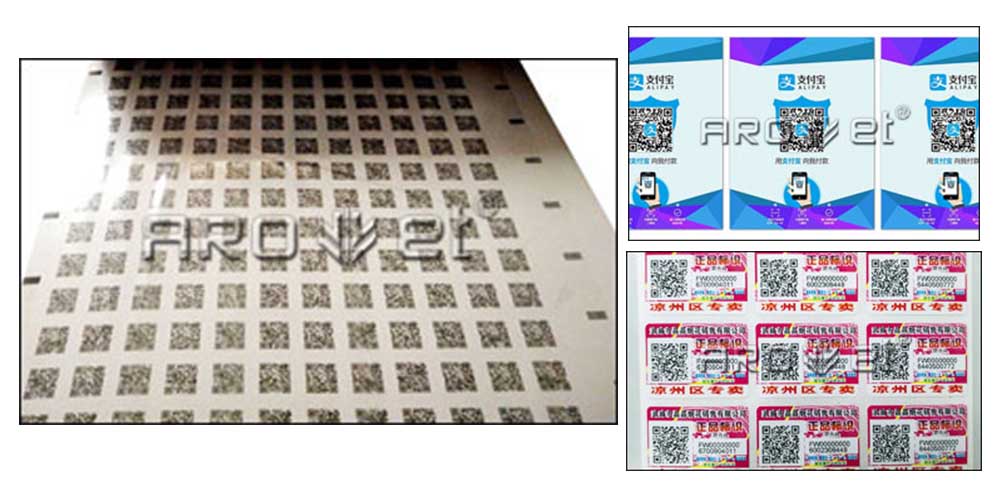

Product Applications

◇ High-speed flexographic press

◇ High-speed full rotary label printing machine

◇ High-speed gravure press

◇ Automatic inspection machine

◇ High-speed slicing & slitting machine

◇ Varnishing and laminating machine

◇ Paging machine

◇ Plastic, wallpaper, advertising cloth, glass, wooden board, ceramic tile, metal plate, PVC plate, corrugated board, etc.

◇ Variable two-dimension code, one-dimension code, character, number, image, etc.

◇ Textile and clothing

◇ Electronics, hardware

◇ Food, beverage and wine

◇ Medicine, drug and health care product

Print Head

SP-9600 model adopts KYOCERA industrial piezoelectric print head, with 108mm wide format, which can print much wider content with fewer print heads. Dense ink droplet stable jetting with 2656 nozzles per head and high image quality of 600dpi and five-level grayscale, enable it to achieve high precision and high definition printing effect and bring new opportunities for your business expansion.

※ Ceramic nozzle, high resolution and long service life.

※ Four kinds of ink droplet size.

※ Powerful nozzle compensation function.

※ Automatic substrate thickness measurement. Printed substrate thickness can be up to 50mm.

Printing Software

Model SP-9600 adopts AROJET MagicData printing software, which is customized for variable data inkjet printing. It offers a human-friendly interface to interactively set printer options, manage and maintain print head, and monitor printing status. With easy operation and maintenance of the printer, MagicData greatly enhance print productivity and efficiency. The software provides interface to support the second development, to achieve versatile inkjet printing applications.

※ Ink drop size setting.

※ Print head temperature setting.

※ Automatically print selected job in fast mode.

※ Customized template and layout design.

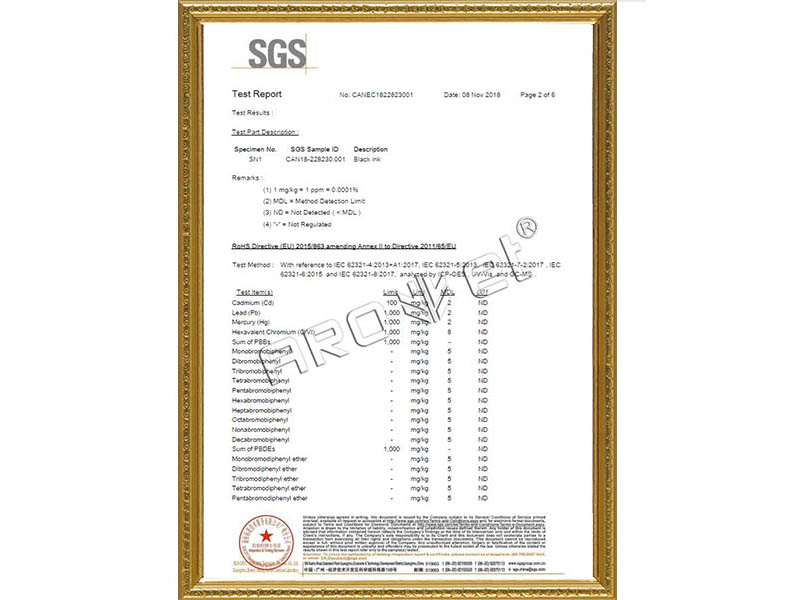

Printing Ink

AROJET wide-format inkjet printer model SP-9600 uses high-quality UV ink. Compared to ordinary ink, UV ink has relatively stable physical properties. It is non-flammable, safe and convenient to transport and use, with no corrosion and no volatility. After inkjet printing, the UV printed content passes through the UV-LED curing system very fast to achieve quick drying. The cured UV ink is high-adhesion, anti-corrosion and friction-resistant with good uniformity, high vivid and excellent quality. UV ink is widely applied to printing industry, provides more delicate and high quality printing to many industries.

AROJET attaches great importance to the ink safety, provides MSDS report of the ink and conducts regular SGS testing for the inks.

※ Eco-friendly. The ink test result conforms to RoHS standard.

※ Outstanding printing adaptability.

HW-G4

Grinding width 450mm,is the smallest size among the planetary gear structure series.Planetary plates rotate toward different direction,which increase working performance.

Application

HW-G4 can be used for floor coarse grinding, medium grinding, fine polishing, crystallizing, preparation, maintenance. It is not only applied for concrete, but also for millstone, marble, granite, and terrazzo floor.

Model | HW-G4 | |

Voltage | 380V-440V, 3Phrase | 220-240V, 1Phrase |

Frequency | 50/60HZ | 50/60HZ |

Current | 11A | 15A |

Power Output | 5.5hp(4kw) | 5.5hp(4kw) |

Inverter Power | 5.5hp(4kw) | 5.5hp(4kw) |

Motor Speed | 300-1600rmp | 300-1600rmp |

Grinding Cover Width | 500mm | 500mm |

Grinding Width | 480mm | 480mm |

Disc Diameter | 200mm*3pcs | 200mm*3pcs |

N.W | 191KG | 191KG |

Water Tank | 20L | 20L |

Dimension | 970*500*800mm | 970*500*800mm |

PRE-SALE SERVICE

Once receive your question,we will offer you a total solution.

We offer 7/24 hours online service.(E-mail,Whatup,Facebook,Youtube,Twitter,etc)

Telephone and Mobile phone are also available,you can contact us in everywhere and any-time.

IN-SALE SERVICE

All the machines’ parts have pasted the quality control system before,during and after manufacturing.

We ensure that you’ll receive the machines within 15 days.

We ensure every single machine is in TOP quality before you get it.

AFTER-SALE SERVICE

1 year warranty for the machines.

Our strong R&D department offers immediate technology support.

Topwell care service will follow you and your machine for years.

Q:What the planetary design means?

A:G4 is planetary design, which means the the gear box and the three grinding plates rotate in opposite directions.

Q: What is the advantage of planetary design?

A: Planetary design is more powerful and sharp, good at grinding the uneven floor.

Q: if Honway concrete grinding machines are all driven by gear?

A: Except G1,G2, all other models are driven by gear. The machine with gear driven is more powerful and effective than belt driven,but you have to replace the gear oil within 5000 working hours.

Q: How do you guarantee the product quality?

A: Quality is guaranteed by every manufacture process. Machinery is related with precision and accuracy. Honway is equipped with CNC, gear hobbing machines to guarantee the quality;

Q: If you test the gear box before it leaves factory?

A: Of course. The gear box is tested without stop by 48 hours, to check if they rotate smoothly? if they have a unusual noise? if they leak oil?etc.

Q: If the machine vibrates when it works?

A: The planetary grinding machine can't work as smooth as counter-rotation grinding machines, because it has a little contrifugal force. But this force is a very little, even a lady could operate it easily. In some area of shortage of human labor, the ladies also operate the machine to grind floor.

Q: What is the quality of motor and inverter?

A: The motor and inverters are good brand in China and long history in their professional filed. We seldom got the complaints about them.

Q: If HW-G4 could be attached to vacuum?

A: Yes, it can; the diameter of port is 50mm, common criteria.

| Model | SP5232B |

| Drilling Capacity | 32 mm |

| Swing | 450 mm |

| Spindle Taper | MT4 |

| Spindle Travel | 120 mm |

| Spindle Speed Step | 12 Steps |

| Spindle Speed | 150 - 2,450 / 180 - 2,940 rpm |

| Maximumn Distance from Spindle Axis to Surface of Column | 255 mm |

| Maximumn Distance from Spindle End to Surface of Worktable | 745 mm |

| Maximumn Distance from Spindle End to Surface of Base | 1,205 mm |

| Column Diameter | 92 mm |

| Height | 1,710 mm |

| Worktable Size | 420 x 480 mm |

| Base Size | 500 x 450 mm |

| Motor Power | 1,100 / 1,500 w |

| Net / Gross Wieght | 145 / 153 kg |

| Packing Size | 1,420 x 650 x 310 mm |

Copyright © 2025 Guangdong Arojet Ink Jet Technology Co., Ltd. | Todos los derechos reservados.

Hola, por favor, deje su nombre y envíe un correo electrónico antes de chatear en línea para que no extrañemos su mensaje y contactarlo sin problemas.